Ultra-High Speed Boxed Biscuit Food Checkweigher

Product Description

The boxed biscuit food checkweigher is designed for fully automatic packaging lines. When overweight or underweight products are detected, the product conveyor belt will stop and alarm, and the screen will display the weight. When unqualified products are removed from the production line, the belt will automatically run. The ultra-high-speed box checkweigher has excellent versatility and can provide weighing results with high accuracy and high speed, with the highest reliability, and perform strict quality inspection.

Ultra-High Speed Boxed Biscuit Food Checkweigher Video

Parameter

| Type | SG-150HH |

| Weighing Range | 3-500g |

| Limited of product | L: 100 W:150 H: 2-150mm |

| Accuracy | ±0.1g Depends on product |

| Division Scale | 0.1g |

| Belt Speed | 0- 110 m/min |

| Max Speed | 450 pcs/min |

| Belt Width | 150mm |

| Machine Weight | 140kg |

| Power Supply | AC-220V 50HZ |

| Power | 200W |

| Main Material | SU304 stainless steel |

High Accuracy Checkweigher for Food Details

Features

Automatic sorting - automatic sorting method, convenient and fast;

Adjustable speed - high-precision detection, adjustable conveying speed;

Parameter setting - upper and lower weight limit parameters can be set arbitrarily;

Variable frequency speed regulation - the conveying system adopts variable frequency speed regulation mode, which is convenient for speed regulation;

Data storage - powerful data statistics function, recording daily detection data;

Data call - with set data group memory, call function, easy operation;

Data recording - OK number, underweight number, overweight number are accumulated separately;

Fault diagnosis - self-fault diagnosis and prompt function, convenient maintenance;

Multi-group storage - can store 100 groups of set parameters for storage;

Processing method - unqualified product alarm/shutdown, rejection is optional;

Data viewing - historical record query function, can be exported to USB flash drive, and can be viewed directly with office PC.

Application

A-Food and Beverage Industry: Accurately reject empty, underweight, overweight packages

B-Pharmaceuticals: Accurately reject packages without instructions or unqualified weight.

C-Electronics Accurately reject missing instructions and missing parts packages.

D-Agricultural and sideline products: Used to classify the specifications of products such as fruits, vegetables, meat, fish, seafood, etc., and reject unqualified products.

E. Light Industry and Daily Chemicals: Reject missing, empty and damaged packages.

F. Logistics and Express: Sorting packages according to weight and additional requirements, coordinated with data input instruments.

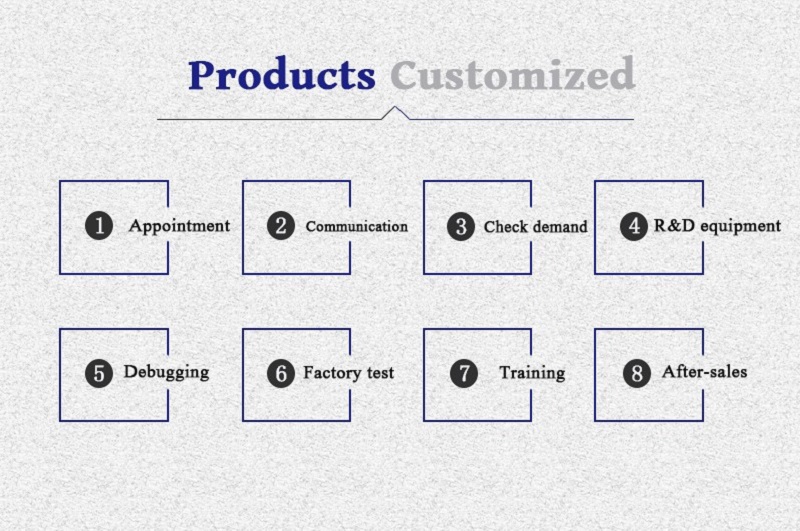

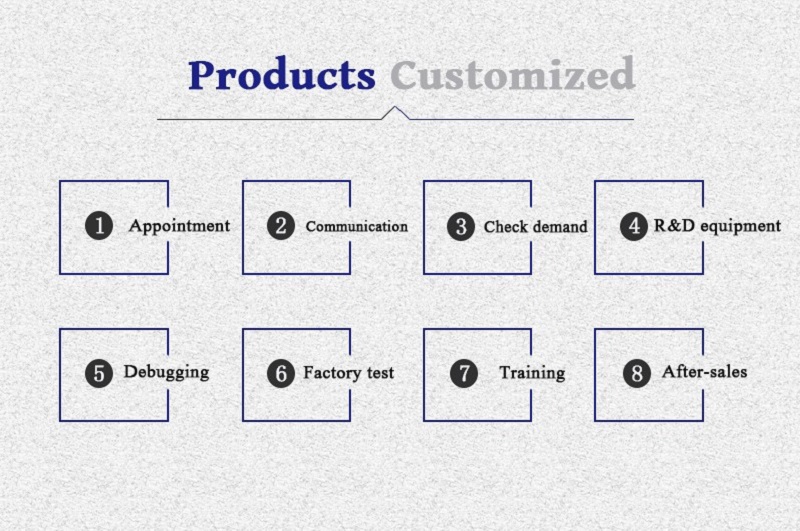

Customization Service

Most of our goods are customized according to specific project requirements.

If possible, please let us know more details about your project, such as material, weight range, speed, bag size, etc.

It is best to contact us in advance before ordering.

Sale Service

A.Pre-sales

project design,performance introduction,technical agreement,contract signing,production testing and we can customized production according to your requirements.

B.In-sales

we will provide you with the latest process in the product assembly,packing and transportation.

C.Installation

1.We provide videos and instruction manual to show the process of installation.

2.We provide training for installation for free in our factory.

3.We can send technician to buyer's factory to install the machine and provide training service.

D.After-sales

1. For our machines, we will provide some spare parts and easy broken parts free of charge when delivering.

2.We will have one year free warranty period. During warranty period, if there is any malfunction for the machine, we will try our best to solve the problem within 24 hours. If there are some spare parts needed to be replaced, we will provide the spare parts for free. Beyond warranty, we will charge the cost price for spare parts.

3.We provide technical support for our machines for life-long time. We can provide installation and maintenance service at your place if you need.