High Sensitivity Conveyor Belt Metal Detector for Packaging Industry

Description

The metal detector for packaging industry is used to detect various metal impurities such as metal chips, broken needles, iron wire, lead, copper, aluminum, tin, stainless steel, etc. that are mixed or lost in raw materials or products. It is highly intelligent. The special design of the digital conveyor belt metal detector structure can effectively avoid interference from external factors such as vibration, noise and product effects. The conveyor can provide a belt conveyor or a modular chain conveyor, and the detection head can also be directly installed on the inclined chute for detection. Our products have a wide range of specifications, sizes, and styles, providing various customized solutions. Welcome to contact us.

Metal Detector for Packaging Industry Photos

Parameter

|

Detection method |

Electromagnetic wave detection, a combination of new analog circuits and digital circuits |

|

Display |

7/10-inch color touch screen |

|

Effective detection width |

40cm (customizable according to customer needs) |

|

Effective detection height |

10-20cm (customizable according to customer needs) |

|

Sensitivity adjustment |

100 levels |

|

Detection sensitivity |

0.8-3.0mm iron ball, 1.5-5.0mm stainless steel

Alarm method: buzzer alarm, motor automatically stops

|

| Belt Width | 220mm |

| Machine Weight | 85kg |

| Power Supply | AC-220V 50HZ |

|

Conveyor belt speed |

20m/min (customizable according to customer needs) |

| Main Material | SU304 stainless steel |

Metal Detector for Packaging Industry Photos

Features

1. Double-circuit electromagnetic wave detection, a new combination of analog circuit and digital circuit, improves the sensitivity and reliability of detection

2. New software algorithm and large-scale integrated circuit composition improve the intelligence of detection

3. Humanized interface design, avoiding language operation, the whole process is simple and intuitive, and the human-machine interface is clear at a glance

4. Dynamic zero-point voltage tracking, automatic learning detection function, reducing personnel operation

5. Multi-frequency scanning, wide sensitivity adjustment range

6. When metal is detected, sound, light, and alarm are issued simultaneously, the machine stops or unqualified products are rejected (multiple rejection methods can be selected)

Application

High sensitivity conveyor belt metal detectors are widely used in food, medicine, aquatic products, toys, clothing, footwear, chemicals, leather, knitting, printing and other industries to detect metal impurities mixed in products or raw materials during the production process, improve product safety factors and reduce hazards.

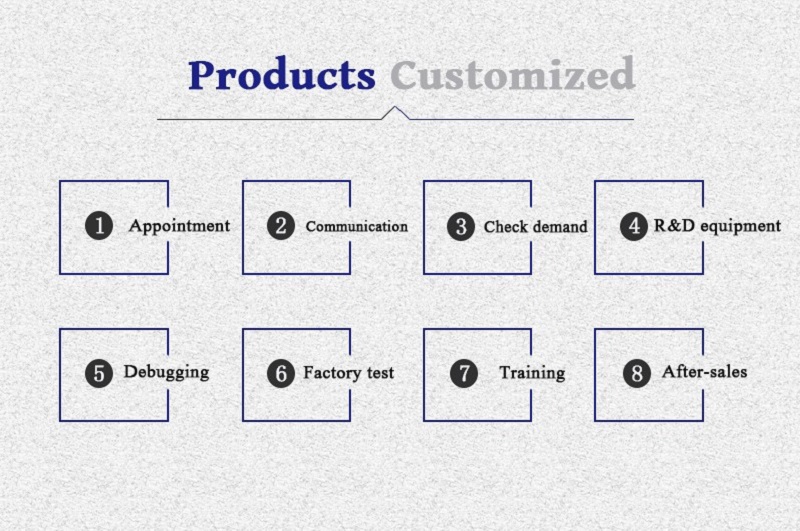

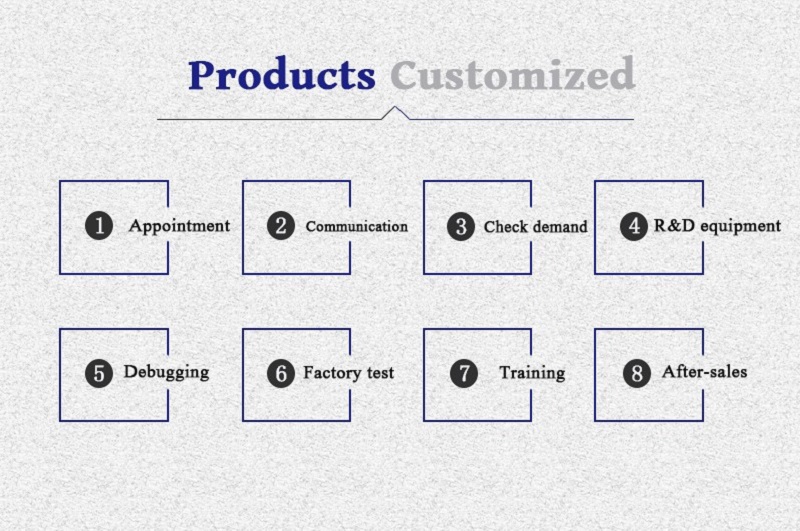

Customization Service

1. Flexible digital metal detector solutions

Customized according to specific requirements based on production line space, speed, detection accuracy, and impact on materials.

2. Rich peripheral interfaces

Configurable RS-485 data communication, PLC programming nodes, printer output, can provide real-time data for production management system for remote control, analysis and monitoring, and provide valuable traceability information

3. Efficient rejection device

Equipped with rejection devices such as arm-type, air-blowing type, flap type, lifting belt type, etc.

Application

Machine packing :

Non-fumigation wooden case for export standard and comply with customs clearance requirement

Lead time :

10-15 days after payment received

Price term :

FOB term, CIF/CFR term(sea/air), DDU/DDP term( sea/air)

Negotiable payment term: T/T , LC, D/P ,D/A .,etc

Sale Service

Q1: What is machine warranty?

Machine warranty for one year. During the warranty period, any non -vulnerable part of the machine is damaged. We will replace it for you for free. After the warranty date is issued by the machine, we receive the bill of lading.

Q2: I have never used this high sensitivity conveyor belt metal detector . How can I control it?

1. Each machine has related operation descriptions.

2. Our engineers can operate through video demonstrations.

3. We can send engineers to on -site teaching. Or welcome you FAT before installation.

Q3: Will you show us the following details when inquiry?

We can.

1. Product size (description/photo/sample can be)

2. accuracy

3. Speed

4. Other requirements