High Performance Industrial Box Checkweigher Machine

Industrial Box Checkweigher Video

Description

Parameter

| Type | SG-300U |

| Weighing Range | 5-3000g |

| Limited of product | L: 350 W:300 H: up3mm |

Accuracy |

±0.3g-0.5g Depends on product |

| Division Scale | 0.1g |

| Belt Speed | 0- 60 m/min |

| Max Speed | 80 pcs/min |

| Belt Width | 300mm |

| Machine Weight | 85kg |

| Power Supply | AC-220V 50HZ |

| Power | 200W |

| Main Material | SU304 stainless steel |

High Accuracy Checkweigher for Food Details

Features

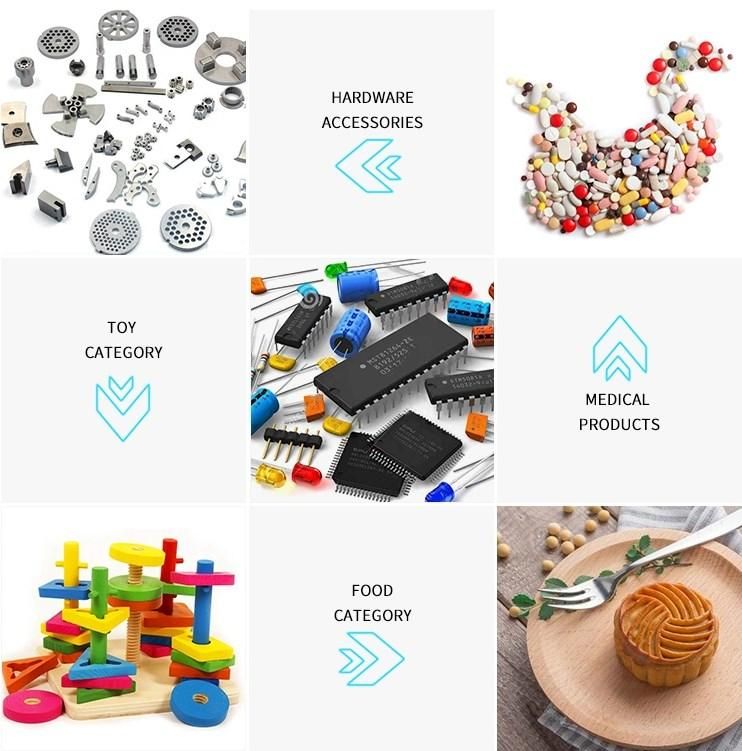

Application

Customization Service

1. Panel tumover type checkweigher

Stretching baffle to separate faulty items; It is fit for packet content with thickness of le such as tablet, electuary and the like.

2.Dropped type checkweigher

Dropping carrier plate to separata faulty items with great area; Others eliminate items that is thin, difficult to slide and easy to damage.

3.Air-sweeping type checkweigher

Using strong airflow blow to separate faulty items; It is fit for high-speed packet content like lightweight items.

4.Push type checkweigher

It is common elimination method applicable to box-packed items with thicker packing; It is usually standard configuration of equipment.

5.Driving lever type checkweigher

Driving lever to separate faulty items, which is equivalent to push type. It is common elimination method.

Packaging

Packaging

Film pack inside, Wooden case outside

Shipping

1. Upon receipt of payment, delivery date will be in 20-30 working days

2. By Air, by Sea or by Express (DHL, UPS, TNT, EMS, etc.)