Dynamic Pharmaceutical Blister Checkweigher Packaging Line

Pharmaceutical Blister Checkweigher Information

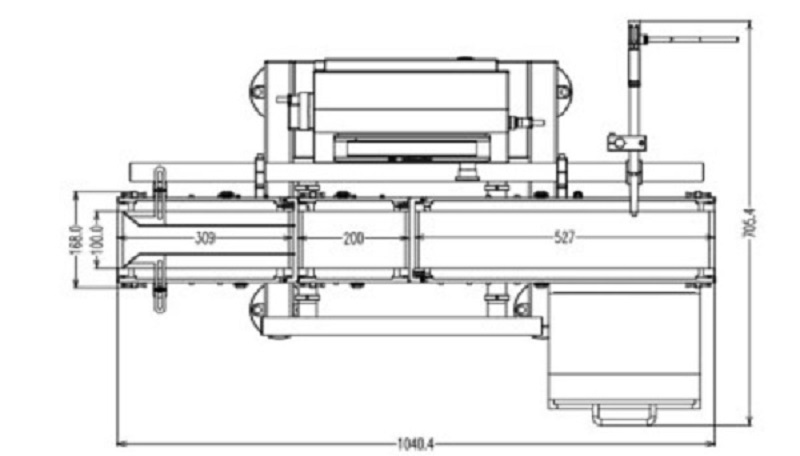

Parameter

| Type | SG-100 |

|---|---|

| Weighing Range | 2-300g |

| Limited of product | L: 100 W: 100 H: 2-150mm |

Accuracy |

±0.05g Depends on product |

| Division Scale | 0.01g |

| Belt Speed | 0- 90 m/min |

| Max Speed | 260 pcs/min |

| Belt Width |

100mm |

| Machine Weight |

70kg |

| Power Supply | AC 220V ±10% 50HZ |

| Power | 100W |

|

Main Material |

SU304 stainless steel |

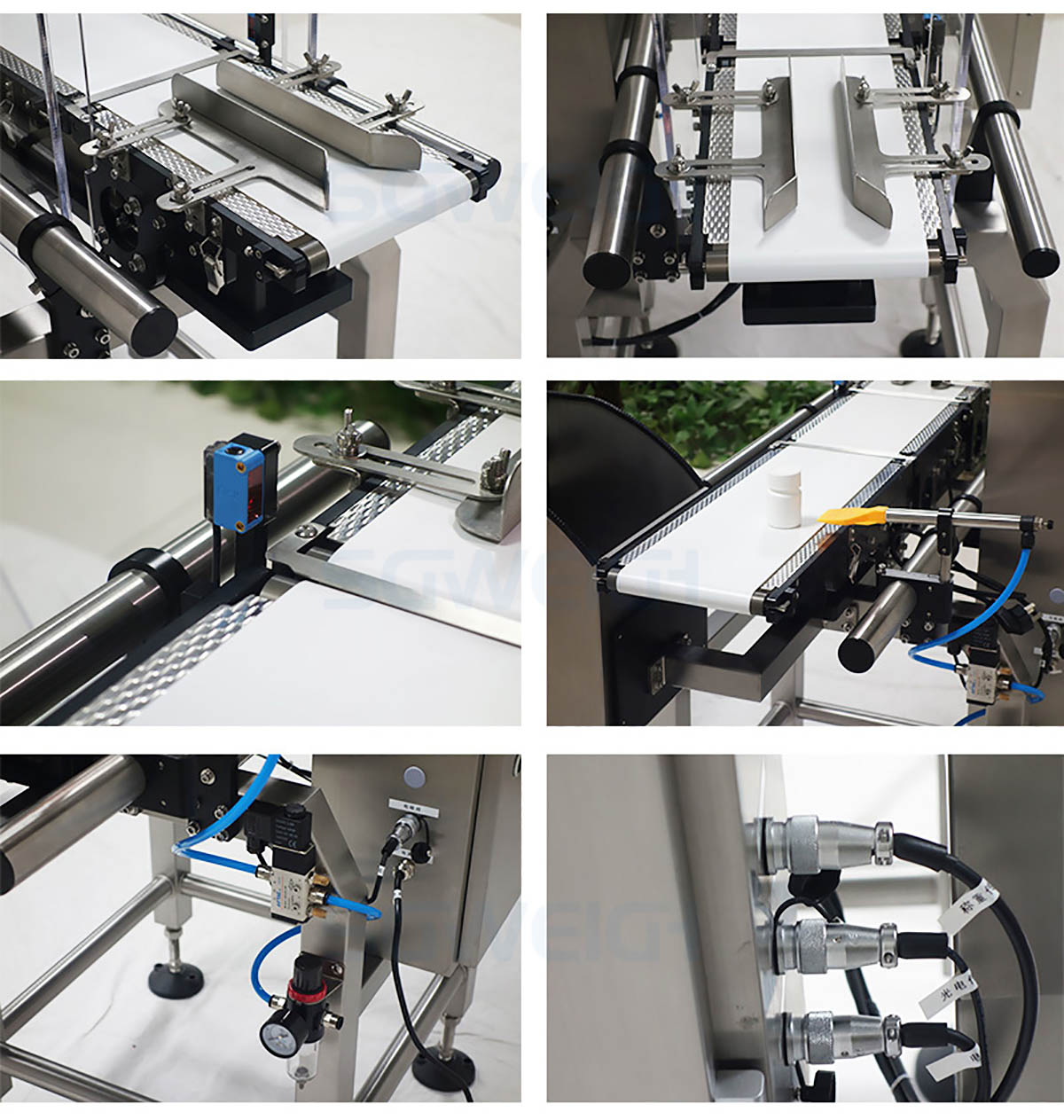

Details

Features

Application

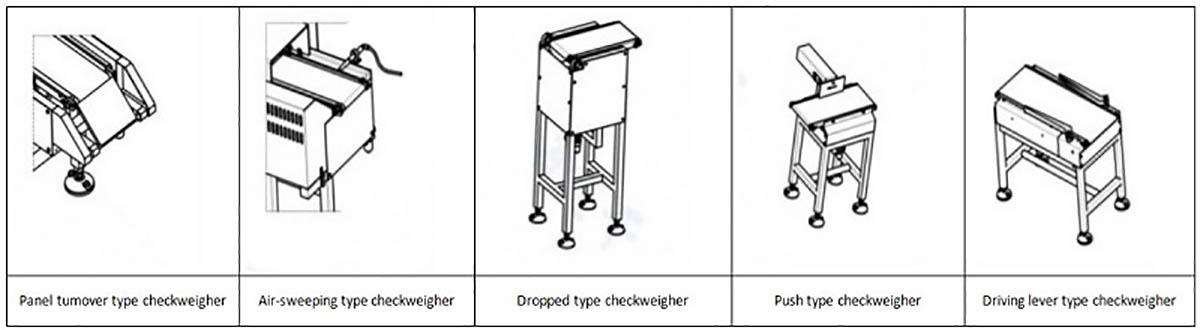

OEM/ODM Service

Our Company

Packaging & Shipping

FAQ

Q1: What is machine warranty?

Machine warranty for one year. During the warranty period, any non -vulnerable part of the machine is damaged. We will replace it for you for free. After the warranty date is issued by the machine, we receive the bill of lading.

Q2: I have never used this online checkweigher machine. How can I control it?

1. Each machine has related operation descriptions.

2. Our engineers can operate through video demonstrations.

3. We can send engineers to on -site teaching. Or welcome you FAT before installation.

Q3: Will you show us the following details when inquiry?

We can.

1. Product size (description/photo/sample can be)

2. accuracy

3. Speed

4. Other requirements