Automatic Multi-lane Packing Machine for Beverages

Prodcution Information

The multi-lane packing machine for beverages liquid is an advanced and efficient solution designed specifically for packaging shampoo and detergent in small bags. Automatic multi lane liquid packing machine with excellent speed, accuracy, and versatility, this packaging machine is the perfect choice for enterprises seeking efficient and reliable packaging solutions.

Parameter

|

Model |

8/10 Lane packaging machine |

|

Sealing method |

3/4 side sealing of small bags |

|

Speed |

20-40 bags/minute per channel (depending on product type and filling quantity) |

|

Maximum bag length |

150 mm |

|

Filling range |

1 ml to 50 ml of liquid and paste, 1 g to 40 g of powder |

|

Packaging products |

liquid, paste, viscous powder, and free flowing powder |

| Main Material | SU304 stainless steel |

Features

1. The multi-lane packing machine for beverages liquid can produce bags in multiple lanes simultaneously.

2. Main functions of the machine: automatic film opening, liquid metering filling, multi-channel bag filling and sealing, cutting, sensor tracking, and counting ability.

3. Other functions: emergency stop, setting the ability to automatically stop the machine, counting ability and zero counting, preparing luggage output, manually testing each step of the machine, etc.

4. Stainless steel contacts and machine casing, high-performance and suitable for liquid operating environments.

5. High precision photoelectric sensors are used to automatically track eye marks on the film, so each bag can be cut at precise positions.

6. PLC controller, powerful in function, can control the working steps of the entire machine.

High Accuracy Checkweigher for Food Details

Application

The multi column liquid bar filling and packaging machine is suitable for various liquid products, such as tomato sauce, honey, sauce, oil, paste, rock sugar, etc.

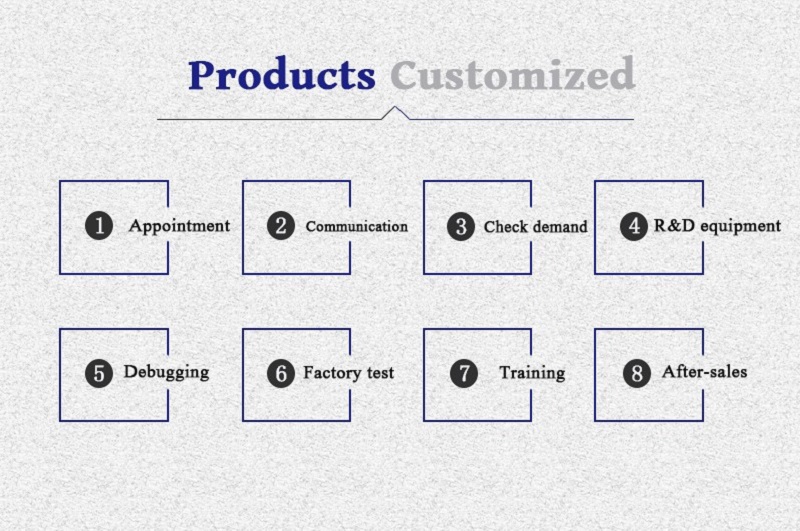

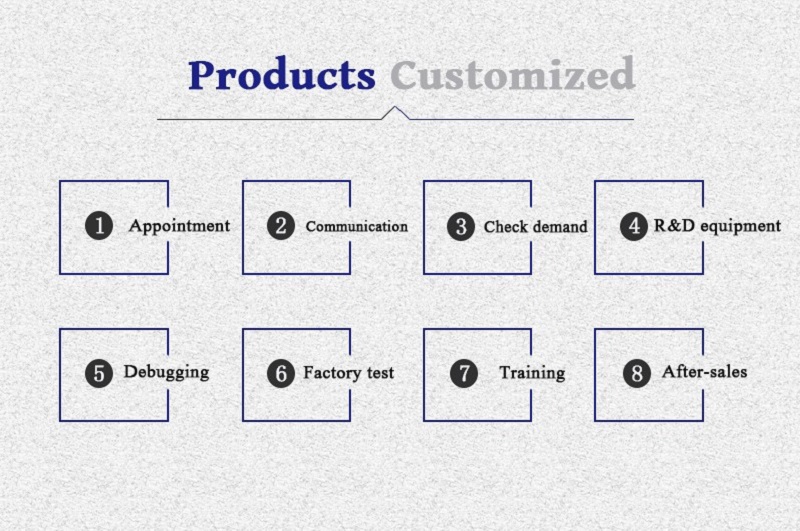

Customization Service

We are a manufacturer of particle, powder, and liquid multi-lame packaging machines that can be customized according to your requirements. Please provide us with the following information when you inquire about our price. Based on your information, we will recommend the best solution for your reference. Thank you.

1. Bag size

2. Bag weight

3. Your product

4. Bag shape

5. Bag material

Sale Service

1. Service tenet: Shanghai Shigan Industrial Co., Ltd. is committed to providing customers with fast, decisive, accurate, thoughtful, and thorough services to meet their equipment needs.

2. Service objective: The company takes high-quality service quality as the standard, aiming to win the satisfaction and trust of users.

3. Service efficiency: The company promises to provide effective solutions within 24 hours in case of equipment failure, ensuring that customer production progress is not affected.

4. Service principle: The company's product warranty period is twelve months. During the warranty period, for equipment damage caused by quality reasons, the supplier will provide free repair and replacement parts. If the equipment parts are damaged outside the warranty period, the supplier will only charge the cost price. For equipment damage caused by customer human factors, the supplier's repair or parts provision will be calculated at cost.